Chanel introduces eco-friendly beauty li...

Chanel has unveiled N°1 de Chanel, a new generation of eco-responsible beauty products that are formulated with up to

Chanel has unveiled N°1 de Chanel, a new generation of eco-responsible beauty products that are formulated with up to

US-based baby food company LactaLogics has finalised a partnership with flexible packaging manufacturer Scholle IPN f

€4 million investment segregates baby milk powder tins production, paves way for further growth with space for additional line.

a global provider of high-quality packaging for infant-food, nutritional and wellbeing products, has upgraded its manufacturing facility in The Netherlands to include a dedicated tins production line for baby milk powder products. Now installed and operating in a segregated room for food-grade compliance, the new line is currently servicing a major customer in the baby milk sector.

Hoffmann manufactures its tins supplies with BRC/IoP GS 6 and ISO 9001 production standards, applicable for major markets like the EU, US and China. The €4 million investment brings the capability to expand its baby milk powder tins capacity by 118 million pieces per year. Currently, the line is producing 99mm diameter cans with volumes of up to 400 grams (0.88 lbs.). The newly dedicated room also has space for a second production line to accommodate continued growth.

The expanded capacity and new sustainable product lines also come with a reorganized leadership team. To ensure alignment across its two tins production facilities in Switzerland and The Netherlands, Hoffmann has streamlined its executive structure to hold responsibility over the entirety of its growing metal packaging business unit.

First, Metal Business Unit managing director Andreas Geiger is departing Hoffmann Neopac Group after two years leading the tins business. André Seiler has taken over the tin division’s management, and will commute between the two main production sites in Switzerland and The Netherlands. Mr. Seiler is a longtime metal processing industry professional, including tenure as managing director for Stebler Blech AG and Stebler Packaging AG in Nunningen, Switzerland. He is the current president of the Swiss Metal Association (SVM).

In addition, packaging industry expert Karin Paldanius will join Hoffmann on February 1, 2022 as Director Sales, TINS. Ms. Paldanius comes to Hoffmann with far-ranging experience in both the packaging and production sectors.

Finally, sales director Tomas Pivko has decided to reduce his workload He steps back from the Executive Board and serves as a key account liaison.

“The new dedicated baby milk powder tins line at our facility in The Netherlands further cements Hoffmann’s standing as a European specialties producer in the metal packaging sector,” said Mark Aegler, CEO of Hoffmann Neopac. “We are excited to welcome new team members and like to commend both Andreas Geiger and Tomas Pivko for the exemplary work they’ve done to grow and transform our packaging business over the past decade. For the future, we continue investing heavily in decarbonizing our production sites and products, thereby reducing our overall impact in the steel packaging supply chain.”

About Hoffmann Neopac

Hoffmann Neopac is a privately-owned company, headquartered in Thun, Switzerland. The group produces high-quality metal and plastic packaging in six locations: HOFFMANN tins in Thun and Holland; Polyfoil® and plastic tubes with NEOPAC in Switzerland, Hungary and the US; and 3D Neopac in India. Its longstanding customers include pharmaceutical, cosmetics and consumer goods manufacturers in the European, North American and Asian markets.

Including its new production facility in the United States, Neopac employs around 1,250 employees and has a capacity of 1.3 billion tubes. The company is dedicated to sustainability in both its manufacturing processes with renewable electricity and corporate culture, including a dedicated eco-conscious packaging portfolio. For more information, visit www.hoffmann.ch.

Having spent north of $50 million to date refining its plastic pallet offering, Ben Stoller, Paxxal’s CEO, states tha

As many of you are aware, PET beverage containers are often wrapped with PET-G (or sometimes polyvinyl chloride aka P

Iceland is replacing its previous packaging with Mondi’s versatile functional barrier paper across a number of its ra

A new stackable jar from Berry Global offers a valuable space saving solution on retail shelves, through e-commerce channels and in the home. At the same time, the jar provides excellent consumer convenience, and its effective product protection, reusability and recyclability enhance its environmental profile.

The innovative design of the 500ml Staka jar incorporates a 63mm recess in the base into which the accompanying 63mm cap, also from Berry as part of a complete container and closure solution, fits snugly. This allows the jars to be easily stacked and remain very stable.

The cap itself can be specified in a variety of colours, while the eye-catching ‘square round’ design of the Staka jar is ideal for labelling or sleeving, creating excellent brand identity and individuality on shelf.

For food manufacturers and processors, the wide mouth of the jar ensures easy filling. Its multilayer construction also allows hot filling and delivers effective product protection for an extended shelf life that helps to minimise food waste.

The jar provides safe and easy handling for consumers. After use, it is ideal as a storage container and can be recycled where appropriate recycling facilities exist.

This latest design underlines Berry’s expertise in devising solutions in line with customer requirements, as John Richardson, General Manager of the Berry Corby facility, explained:

“Many of our customers have approached us recently, keen to develop stackable jars for all sorts of products from spices and sauces for our food clients to lubricants in the commercial sector, so we feel confident that there is a need for this design.”

For more information on Berry’s wide range of packaging solutions, visit www.berryglobal.com.

Extendable for evolving output demands, VI 5 & VC 5 Vertical Cartoners offer premium positioning precision and rapid product changeover in optimized footprint.

IWK Packaging Systems, Inc., a manufacturer of premium cartoning and tube filling equipment for the pharmaceuticals and health & beauty sectors, has introduced a pair of versatile vertical cartoners – one intermittent, one continuous – that provide premium cartoning capabilities at comparably cost-effective price points. Defined by modular extendability, high levels of positioning precision and fast changeovers, both machines are attractive options for pharma or personal care manufacturers cartoning a wide range of containers.

First, the VI 5 Vertical Cartoner is an intermittent motion machine with an open, accessible work area and a modularly extendable length that optimizes floorspace. Suitable for a wide array of containers including bottles, tubes, blister packs, jars, pouches and bags, the touchscreen-operated VI 5 can produce up to 75 cartons per minute, with a format range of 25-100mm long, 20-90mm wide and 50-230mm in height.

Among the VI 5's key highlights is the ability to change formats exceptionally quickly. This functional versatility is aided by easy, repeatable changeover steps, a centralized transport height adjustment system, and carton buckets expediently exchangeable through a click system. No adjustment of rails is needed along curves, further expediting product switches.

The VI 5's servo-driven, cam-guided transport system offers premium positioning precision. The basic machine comprises 22 carton carriers and a corresponding number of stations; optional transport system extensions can bring the total number of stations as high as 54. Other options, including a leaflet feeder and automatic product loading, also are available.

Meanwhile, IWK's VC 5 Vertical Cartoner is a continuous motion module that can produce up to 120 cartons per minute. Like the VI 5, the VC 5 also features an open, ergonomic work area and an extendable length that optimizes its footprint. Easy to clean and touch-screen operated, the unit offers semi-automatic packing of a broad range of containers, including bottles, tubes, blister packs, jars, pouches and bags.

Like its sibling machine, the VC 5 can handle a format range of 25-100mm long, 20-90mm wide and 50-230mm in height. Exceedingly fast changeover is another commonality, as is exemplary positioning precision via its servo-driven, cam-guided transport system. The basic VC 5 contains 40 carton carriers and a corresponding number of stations, with extensions available to bring that total as high as 68. Other options include a leaflet feeder, automatic product loading, and a rejected carton compartment.

“Each of these new cartoners offers extraordinarily high levels of functionality at a surprisingly cost-effective price point,” said Bernie Conlon, Managing Director of IWK Packaging Systems, Inc. “Our goal was to make many of the best aspects of IWK cartoners – including handling versatility, precision positioning and modularity for evolving needs – available to a broader set of customers in the pharma and personal care products spaces.”

About IWK Packaging Systems, Inc.

For over 125 years, IWK Packaging Systems has designed and engineered cutting-edge tube filling and cartoning machines for a wide variety of industries, predominantly the pharma and health & beauty sectors. Leaning on modern technology while standing on the shoulders of prior successes, the company’s equipment is known for offering outstanding performance and unsurpassed reliability.

IWK’s main objective is to keep its customers’ operations running with maximum productivity. To help ensure this, more than 15% of the company’s workforce is dedicated to pre-sales engineering concepts and aftersales service. IWK currently supports more than 10,000 packaging systems around the world with rapid response times and 24/7 service availability. For more information, visit www.iwk.de/en.

BoƩa Packaging, Italy, are taking their sustainability services one step further. In addiƟon to offering top quality sustainable packaging opƟons they are now going to ensure their customers can truly minimise their environmental impact by offering carbon-offseƫng as a service.

BoƩa are known for helping their customers achieve their sustainability goals by providing innovaƟve sustainable packaging soluƟons. Despite this, BoƩa recognise there was more they could do. Their challenge was that most of their packaging was already low impact. Corrugated cardboard boxes and paper-based packaging come from sustainable sources. They can be recycled numerous Ɵmes and even be made out of recycled materials, making them a valuable part of the circular economy. So where else could BoƩa help customers make impact reducƟons?

They will always look to reduce the impact of their packaging first. But there are impacts that by their nature cannot be removed completely, including producƟon and transport emissions. It is these emissions that BoƩa is offering to offset as a service to customers. This service will include reports that can Ɵe in with their customers’ exisƟng environmental reporƟng systems.

As packaging is so oŌen the first thing a customer sees of a business, customers can have their climate neutral packaging cerƟficaƟon printed on the packaging alongside a QR code that links through to the cerƟfied project the company is contribuƟng to. This way customers’ commitments can be easily communicated.

“We know that for our customers, reducing their impact is not only the right thing to do for the planet, but also the right thing for their business. Helping them to remain ahead of the game when it comes being sustainable at every stage of their value chain. It is a very real threat these days to lose out to a compeƟtor who can offer more sustainable soluƟons and alternaƟves. We want to help protect our customers and their reputaƟons by offering them every opƟon possible to achieve their sustainability goals and remain compeƟƟve.” Lara BoƩa, VP BoƩa Packaging, Italy

ABOUT BOTTA PACKAGING BOTTA Packaging is an Italian family company which has been in the corrugated cardboard packaging business for over 70 years. The company has a leading and compeƟƟve experƟse in Eco-friendly packaging. BOTTA Packaging is commiƩed to offer paper-based packaging alternaƟves to its customers, in the mission to help them aƩain their sustainability goals. BOTTA Packaging collaborates and cooperates with UniversiƟes, Companies and Start-Ups to address innovaƟon in the packaging industry, believing firmly in an Open InnovaƟon approach. Its strategy is focused on challenging and pursuing the most avant-garde packaging innovaƟons that can be boosted and enhanced to respond to the packaging sector’s needs, their central focus.

France has banned the use of plastics to package most fruit and vegetables.

A move by a Canadian chocolate maker to produce packaging for blind and partially sighted people is one of several ca

The companies say this is a first-of-its-kind collaboration in Denmark, bringing together leading players from across

Pune: After the Food and Drug Administration (FDA) in Maharashtra issued orders instructing food vendors to not use n

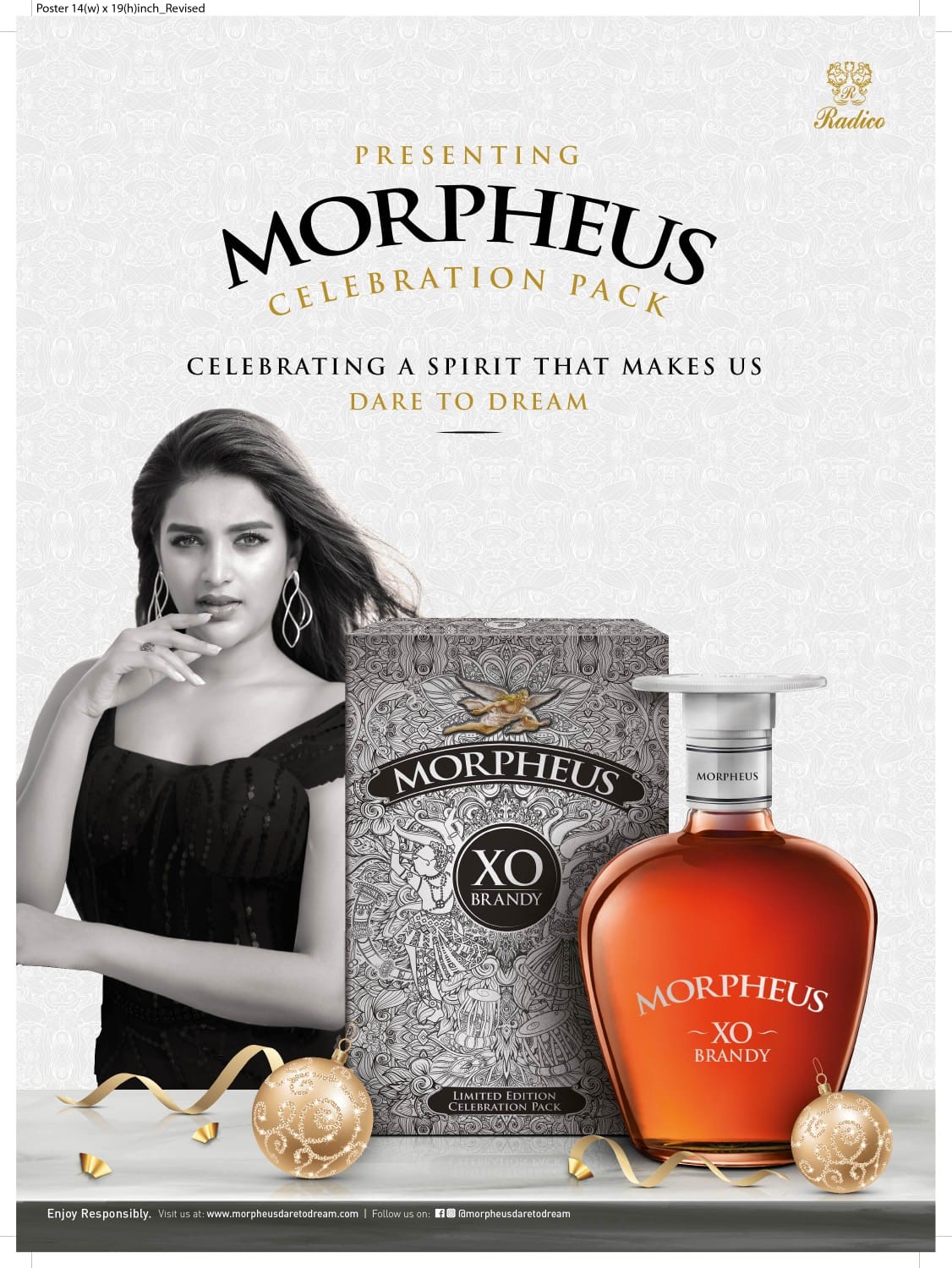

Radico Khaitan Limited, India’s largest IMFL company, kicked off the new year festivities by launching a special edition “Celebration Pack” for Morpheus - India’s largest selling premium brandy. The limited-edition celebration pack will be available across Delhi, Uttar Pradesh, Telangana, Pondicherry and Karnataka in the first week of 2022. With its glorious appearance and arty packaging, the pack is sure to shine among consumers. The celebration pack is also a tribute to the art and crafts community marking a decade of godly craftsmanship of the blend.

Morpheus Premium Brandy, named after the winged Greek God of Dreams, was introduced in 2009 as a pilot to the company’s premiumization drive. A market leader in the category with over 65% of Market Share, Radico subsequently launched a notch-up brand extension, Morpheus Blue XO Premium Brandy to expand the brand to the upper segment. Morpheus Blue was launched in 2013 as a higher variant, following the overwhelming success of Morpheus, the only premium Brandy available across India.

A 360-degree campaign has also been rolled out to strengthen the launch of the Celebration Pack with Nidhhi Agerwal – Superstar of South India Cinema who is also the official Brand Influencer for Morpheus XO Brandy and Morpheus Blue XO Premium Brandy for all its marketing initiatives. A host of offline and online initiatives are underway to amplify the launch of this special edition pack.

Commenting on the launch, Amar Sinha, Chief Operating Officer, Radico Khaitan Limited said, “Morpheus embodies the spirit of celebration. As you celebrate this winter holiday season with your loved ones, let us give you another reason to look forward to 2022 in style with this Celebratory Pack.”

He further added “Morpheus is a hallmark brand for us, and the product's luxurious character allows a more heightened experience to the consumers. Morpheus Celebration Pack is one among the skew of innovative initiatives that are going to take the brand to another level in the years to come. It is a new year gift from us to our loyal consumer base and I am confident that this visual delight would leave a lasting impression on them.”

The pack will be available at the retail until March 2022.

About Radico Khaitan Ltd:

Radico Khaitan Limited (RKL) is one of the oldest and largest manufacturers of Indian Made Foreign Liquor (IMFL) in India. Earlier known as Rampur Distillery, RKL commenced its operations in 1943, and over the years emerged as a major bulk spirits supplier and bottler to other spirit manufacturers.The company launched its first brand 8 PM whisky in 1998 and over the years, has created five millionaire brands and over fifteen organically grown brands. Radico Khaitan Limited is also one of the largest providers of branded IMFL to the Canteen Stores Department (CSD), which has significant business barriers to entry. It has been successfully building its brand equity in international markets and currently exports its products to over 85 countries.

New Delhi, 31st December 2021: Radico Khaitan Limited, India’s largest IMFL company, kicked off the new year festivities by launching a special edition “Celebration Pack” for Morpheus - India’s largest selling premium brandy. The limited-edition celebration pack will be available across Delhi, Uttar Pradesh, Telangana, Pondicherry and Karnataka in the first week of 2022. With its glorious appearance and arty packaging, the pack is sure to shine among consumers. The celebration pack is also a tribute to the art and crafts community marking a decade of godly craftsmanship of the blend.

Morpheus Premium Brandy, named after the winged Greek God of Dreams, was introduced in 2009 as a pilot to the company’s premiumization drive. A market leader in the category with over 65% of Market Share, Radico subsequently launched a notch-up brand extension, Morpheus Blue XO Premium Brandy to expand the brand to the upper segment. Morpheus Blue was launched in 2013 as a higher variant, following the overwhelming success of Morpheus, the only premium Brandy available across India.

A 360-degree campaign has also been rolled out to strengthen the launch of the Celebration Pack with Nidhhi Agerwal – Superstar of South India Cinema who is also the official Brand Influencer for Morpheus XO Brandy and Morpheus Blue XO Premium Brandy for all its marketing initiatives. A host of offline and online initiatives are underway to amplify the launch of this special edition pack.

Commenting on the launch, Amar Sinha, Chief Operating Officer, Radico Khaitan Limited said, “Morpheus embodies the spirit of celebration. As you celebrate this winter holiday season with your loved ones, let us give you another reason to look forward to 2022 in style with this Celebratory Pack.”

He further added “Morpheus is a hallmark brand for us, and the product's luxurious character allows a more heightened experience to the consumers. Morpheus Celebration Pack is one among the skew of innovative initiatives that are going to take the brand to another level in the years to come. It is a new year gift from us to our loyal consumer base and I am confident that this visual delight would leave a lasting impression on them.”

The pack will be available at the retail until March 2022.

About Radico Khaitan Ltd:

Radico Khaitan Limited (RKL) is one of the oldest and largest manufacturers of Indian Made Foreign Liquor (IMFL) in India. Earlier known as Rampur Distillery, RKL commenced its operations in 1943, and over the years emerged as a major bulk spirits supplier and bottler to other spirit manufacturers.The company launched its first brand 8 PM whisky in 1998 and over the years, has created five millionaire brands and over fifteen organically grown brands. Radico Khaitan Limited is also one of the largest providers of branded IMFL to the Canteen Stores Department (CSD), which has significant business barriers to entry. It has been successfully building its brand equity in international markets and currently exports its products to over 85 countries.

For further information please contact:

Radico Khaitan Limited

Megha Chhabra

9990997421, Meghac@radico.co.in

Concept Public Relations India Limited

Priyadarshini Bhan

9609171149, priyadarshini@conceptpr.in

Annual Mondi consumer trend research shows year-on-year growth in online shopping by consumers in Germany and Poland

Silver Surfers (age 55+) are a growing eCommerce consumer segment: nine out of ten shopped online in 2021; 49% bought more online than last year and 5% shopped online for the first time

Demand for sustainable packaging highlighted, with more than three quarters of online shoppers preferring eCommerce packaging that is reusable for returns or easily recyclable

Positive ‘unboxing’ experience inspires repeat purchases

The latest market research on eCommerce shopping and packaging trends in Germany and Poland, commissioned by Mondi, a global leader in packaging and paper, shows that consumers of all ages continue to buy online and are in favour of eCommerce packaging that is ‘green’.

Online interviews with 3,085 consumers in Germany and Poland conducted on behalf of Mondi during the fourth quarter of 2021* showed that an impressive 90% of the surveyed population shopped online in 2021. The data was gathered during the annual peak season for online shopping, between Black Friday and New Year’s, a period in which holiday presents were often bought online due to – once again – the pandemic. In addition to regular online shoppers of all age groups, a rise in the senior generation of shoppers who have entered the digital malls is visible and they seem to enjoy the online experience.

Silver Surfers are here to stay

‘Silver Surfers’ are, and will continue to be, important contributors to eCommerce growth. In 2021 the growing demographic of consumers aged 55+ in Germany and Poland have been buying even more online than they did in 2020. Safety and health reasons during the pandemic motivated 41% of this group to shop online in 2021, but Silver Surfers also say they shop online for convenience (39%), the chance to buy things not available locally (45%), and to get a better overview of brands and offers (52%).

Sustainability expectations driving purchasing behaviour

As shopping online becomes routine, more people of all ages in Germany and Poland prefer packaging that is practical and sustainable. A strong majority of respondents want packaging to be reusable for returns (79%), easily foldable (69%) and recyclable (82%).

Environmentally responsible packaging can be a driver of sales, according to the research. Almost half of surveyed consumers (48%) would be willing to pay up to three Euros extra to receive their online purchases in environmentally friendly packaging.

Unboxing becoming brand loyalty influencer

‘Unboxing’ is the latest example of packaging’s importance to brand loyalty and sales. Awareness of this trend has been increasing over the past three years, and today close to half (44%) of surveyed online consumers have experienced the joy of unboxing, which is particularly valued by people in Poland (50%). More than half (58%) of consumers in Poland say that a nice unboxing experience would convince them to order again from the same online store.

About Mondi Group

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is integrated across the value chain – from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer-centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2020, Mondi had revenues of €6.66 billion and underlying EBITDA of €1.35 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

About Mondi Group eCommerce

Mondi Group offers a full portfolio of eCommerce packaging solutions and products that are fit for purpose, innovative and sustainable by design. We are setting new standards in the industry with our expertise in sustainable materials and product design. Driven by an agile and customer-centric mindset, our extensive network of in-house designers and engineers develop award-winning eCommerce solutions together with our partners. Our focus is on decreasing total packaging costs, reducing waste, and meeting end-consumer needs through a combination of our sustainability expertise and full portfolio of multi-material solutions, including kraft and functional barrier paper, paper bags and corrugated solutions.

Rise Above

Like most Apple announcements, there was mention of a faster chip, a more detailed camera, and a tougher screen.