Pharmaceutical packaging market estimate...

The increasing demand for pharmaceutical packaging in emerging markets owing to better access to healthcare, rising h

The increasing demand for pharmaceutical packaging in emerging markets owing to better access to healthcare, rising h

With a turnover of around 3.7 billion Swiss francs, the tradition-rich company Emmi is the largest dairy processor in Switzerland. Emmi has always been aware of the accompanying responsibility for employees, society and the environment – and acts accordingly in a sustainable manner. One success story is the ReWork process at its Suhr location. Using a WEIMA PUEHLER G.300 ReWork draining press, overfilled or underfilled milk cartons are automatically opened and emptied in order to return the recovered milk to the production process. The result: an efficient resource cycle.

More than a third of all food produced worldwide is wasted. That's reason enough for Emmi from now on to campaign even more strongly against food waste as an official Waste Warrior Brand. As part of this association initiated by Too Good To Go Schweiz, Emmi is fighting for greater awareness among consumers and against waste. The measures in its own companies prove that Emmi is leading by example

ReWork solves the waste dilemma

Modern dairy processing equipment must be designed to be as efficient as possible for profitable operation. However, as with any type of manufacturing, defective goods may be produced. In the case of minimally processed basic products such as milk or cream, this mainly relates to things such as over- or underfilled containers or leaky packaging.

This is where the so-called ReWork process comes into play. The focus is on preventing and using high-quality waste. To ensure this, the contents and packaging must be separated mechanically and be guaranteed to be free of contamination. This is the only way that the recovered milk can be refilled and the beverage cartons recycled.

Emmi has relied on PUEHLER technology for two decades

At the largest Emmi location in Switzerland, in Ostermundigen, they have been familiar with PUEHLER draining and compressing technology for over 20 years. Thanks to the successful collaboration, Emmi is relying on WEIMA as a partner for its new ReWork system with a PUEHLER press as a key component at another large location, namely in Suhr, where milk, cream and butter are primarily produced.

Deputy Site Manager Hans-Peter Steuri explains: "We process around 190 million liters of milk and about 60 million liters of cream. Before using the PUEHLER press, we had to manually open every full piece of waste packaging. That was hardly productive. With WEIMA, we have finally found the right partner for our task."

PUEHLER advantages: high throughputs, hygienic design, compact footprint

Steuri aptly described the stringent demands that the new PUEHLER ReWork press meets: "As a food manufacturer, hygiene is the be-all and end-all. WEIMA machines are user-friendly to maintain, have CIP cleaning and comply with strict hygienic design specifications. In addition to the high throughput, the WEIMA system requires significantly less space than those of other providers – a clear advantage for us."

Actual figures reflect the productivity of the WEIMA PUEHLER G.300 ReWork: in the event of an accident, the machine empties and compresses more than 3,000 liters of liquid per hour (with 1 liter cartons). The press is used for a throughput of approx. 15,000 units per week. Generally, most waste (approx. 90 percent) is process-related and accrues when the filling operation is stopped or restarted. In normal operation, the press processes the waste from the last 24 hours within four hours.

Automated drainage operation

Up to 20 different employees operate the ReWork system during the week. In order to further automate the processes, the machine loading takes place via a compact lifting and tilting device. Like the entire machine body and the discharge conveyor, it is made of stainless steel. The milk cartons collected in plastic boxes are then transported into the large hopper of the WEIMA PUEHLER G.300 ReWork. At regular stroke intervals, the milk cartons are then pressed horizontally in the pressing channel by a pressing cylinder moving against a press plate lowered for the process. This drains the packaging and simultaneously compresses it. A major advantage: the machine can be used flexibly. No conversion for different packaging sizes or types is necessary.

The milk first flows through a round-hole screen into the collection tray under the press channel before it is pumped out into large stainless-steel tanks. With the next press stroke, the emptied packages, now formed into manageable compressed disks with a diameter of 300 mm, are transported away via a discharge tube. The residual moisture of the milk cartons is minimal due to the compaction. The contents have been cleanly separated from the packaging. Both material flows can be flawlessly processed. In the case of the packaging, this means: 100 percent recycling at Emmi.

Partnership on equal terms

As soon as the production waste from the last shift has been processed, fully automatic cleaning, or CIP (Cleaning in Place), follows. Hans-Peter Steuri is very positive about maintenance: "The WEIMA PUEHLER G.300 ReWork is very accessible and clearly designed. This makes maintenance and cleaning easier for us. As a partner, we feel very well supported and are provided expert advice by WEIMA. Their adherence to deadlines is exemplary. We can really always rely on that."

Emmi’s ReWork facility pays off in many ways. It is not only particularly economical and efficient but above all sustainable in dealing with resources. WEIMA PUEHLER G.300 ReWork thus actively supports the Swiss dairy processor in its ambitious environmental goals – away from a linear economy

and towards a recycling-based circular economy. According to Emmi, the volume of waste has already been reduced by ten percent compared to 2017.

About WEIMA:

More than 40,000 machines sold worldwide! For over four decades, WEIMA has been manufacturing rugged shredders and briquetting presses for the disposal and processing of all types of waste. Our machines include single shaft shredders, four shaft shredders, cutting mills, briquetting presses and draining presses. The popular blood orange machines are used in the wood, plastics, paper, metal and waste-to-energy industries.

Made in Germany. Built for the world.

Shredders, briquetting presses and draining presses from WEIMA are exclusively made in Germany and come from production plants in SaxonyAnhalt and Baden-Wuerttemberg. Every year, more than 300 employees work on around 1,200 customer solutions for use around the globe. Long-standing sales and service locations exist in the USA, Poland, India and China. More than 80 representatives supplement this global presence.

The Reifenhäuser Group will exhibit its latest innovations for flat and blown film production at ArabPlast 2021 in Dubai from November 15 to 18 (Hall 8, Booth D104). The trade show is the leading industry event for the plastics and rubber industry in the United Arab Emirates.

The Reifenhäuser Cast Sheet Coating business unit, which specializes in flat films, will be presenting its pioneering solution for producing sustainable PET sheet from up to 100% PET bottle scrap (PCR) for direct food contact. Customers process post consumer recyclate (PCR) on Reifenhäuser MIREX PET sheet lines, not only as an intermediate layer between two outer layers of virgin material, as widely used in the food packaging sector. If required, the film can be made from PCR PET only. The end product meets the highest hygiene standards and can be used safely - even in direct contact with food.

Mark Borutta, Sales & Marketing Manager at Reifenhäuser Cast Sheet Coating, explains: "The use of recyclate and direct food contact were long regarded as a non-feasible combination due to the strict regulations. At Reifenhäuser CSC, we have a ready-to-market technology here that bears the crucial FDA LNO (Letter of No Objection). We therefore open up a major field of application for high-quality, high-volume plastics recycling for our customers. It provides tremendous leverage to push forward an effective, functioning circular economy."

Another highlight of the MIREX PET sheet lines is PCR flake processing without pre-drying. This is achieved on the tried-and-tested co-rotating twinscrew extruder "REItruder". Processors therefore benefit from lower energy costs, as it eliminates the crystallization and drying steps in the process. In addition, the line features a special backflush filtration system for extremely high melt quality and process consistency. The result is perfect optical and mechanical film properties.

Ultra Stretch Blown Film: Innovative stretch process produces all-PE film for flexible packaging

The Reifenhäuser Blown Film business unit specializing in blown film is also exhibiting with solutions that produce sustainable end products. The technology answer here is EVO Ultra Stretch - Reifenhäuser's advanced stretching unit for fully recyclable blown film. It allows customers to produce mono-material composites (all-PE film) for flexible packaging and replace the otherwise usual PET layer with stretched PE. With up to 10 times the stretch rate, the Ultra Stretch stretching unit gives PE film completely new mechanical properties. This is a simple replacement for PET and there is no need to adapt other processing steps. The unique and patented position of the stretching unit directly in the haul-off of the blown film line makes the process particularly stable and efficient. Eugen Friedel, Sales Director at Reifenhäuser Blown Film, explains: "The special feature of our solution is that we stretch the film while it is still hot from the extrusion process, at exactly the right time and without reheating. In addition, this also extends the natural cooling phase until the film is wound and gives the film the time it needs to take on its new properties." The Ultra Stretch process is unique on the market and offers decisive advantages over the otherwise usual process of stretching the film between the take-off and the winder.

Visitors to the Reifenhäuser booth in Dubai will have the chance to experience the impressive Ultra Stretch technology, as well as the latest blown and flat film lines, on a large screen as part of a virtual 360° tour through the Reifenhäuser Film Technology Center.

About the Reifenhäuser Group

The Reifenhäuser Group is the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company supplies high-technology solutions all over the world. With its technologies and the know-how of its 1,750 employees, Reifenhäuser has the world's largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser.

Essentra Packaging will host a free series of industry webinars to help packaging professionals find practical and effective solutions to the labelling of clinical trials, against the backdrop of complex regulatory change.

Titled, ‘The implications on Clinical Trials labelling due to Annex VI changes and patientricity’ the first webinar in the series takes place on 2nd December at 15:00 GMT with interested parties invited to register online for the event.

As well as highlighting ways of dealing with the new labelling demands required under Annex VI of thee Clinical Trials Regulation (Regulation (EU) No 536/2014), members of the Essentra Packaging team will provide guidance and advice to attendees around patientricity. Topics to be covered include direct to patient implications, market challenges including those presented from the pandemic, and what successful secondary packaging solutions exist to help improve patient safety.

“Annex VI will inevitably add more complexity to what is already a highly regulated sector and those involved in clinical trial labelling need solutions,” said Diarmuid Wilson, Business Development Director UK & Ireland at Essentra Packaging.

“In what will be a highly informative, and approachable session our first webinar will aim to provide guidance to those across the pharmaceutical and clinical trials sector.”

Essentra Packaging will also showcase a series of successful case studies during the event, showing how it has supported customers to implement effective clinical trial solutions. The 60-minute session will end with a Q&A session where attendees will have the ability to ask questions in relation to the regulation and requirements for packaging.

Those interested in attending the event should complete this registration form.

Notes to Editors

Amendments to Annex VI – relating to the reliability and robustness of labelled data generated in a clinical trial – will come into force on 31st January 2022, as part of thee Clinical Trials Regulation (Regulation (EU) No 536/2014).

The Regulation harmonises the assessment and supervision processes for clinical trials throughout the EU, via a Clinical Trials Information System (CTIS).

The goal of the Clinical Trials Regulation is to create an environment that is favourable to conducting clinical trials in the EU, with the highest standards of safety for participants and increased transparency of trial information.

ABOUT ESSENTRA PACKAGING

At Essentra Packaging we manufacture and deliver pharmaceutical and beauty packaging solutions that today’s leading brands demand.

From regulatory compliant folded cartons, leaflets, foils and labels to the latest anti-counterfeiting security technologies, serialisation, and bespoke clinical trials packs, we pride ourselves in having the flexibility to create packaging solutions quickly.

Our global footprint and single standard quality system ensure products are always produced to the highest standards, and provide the reliability, agility and knowledge to understand and meet our customers’ needs at a local level.

With sustainability and innovation central to our product development, our many years of experience and long-term partnership approach delivers packaging solutions that protect and enhance our customers’ products, whilst maximising supply chain efficiencies and reducing their environmental impact.

The Product Design team at Ardagh Glass Packaging - Europe, worked closely with Absolut and design agency Brand Union to create the brand’s latest limited-edition bottle: ‘Absolut Voices’, which celebrates the wavemakers and trailblazers of the world and is reflected in the bottle’s ‘sound waves’ design.

Elin Furelid, Global Head of Absolut Portfolio & Design, says:

“Celebrating diverse and different viewpoints has always been in our spirit. We’re continuously inspired by the idea that the world becomes a better place when we come together beyond differences, share good times and empower one another. That spirit is what Absolut Voices is all about.”

The sapphire blue-coloured premium bottle contains an impressive 80% recycled glass, the highest percentage yet for Absolut, which is largely thanks to the high recycling rate in Sweden, meaning more recycled glass cullet is available to Ardagh for use in the furnace.

Maria Persson, NPD Project Manager, Ardagh Glass Packaging - Europe, talks about creating the bottle’s distinctive sound wave design:

”We worked with Brand Union to ensure the design met the creative brief to convey the effect of expanding sound waves rather than ripples of water. The effect of the 360 degree design feature was achieved by creating irregular circles with shallow embossing to give life to the waves. Our Product Design Team created the desired effect using their in-house sculptured embossing technology and expertise to give it a lifelike quality and standout impact”.

“It was exciting to see the first bottles come off the production line in the deep sapphire blue, with light bouncing around the bottle from the edges of the sound wave design.”

The limited-edition bottle is available worldwide in 700ml, 750ml and 1litre.

Ardagh Glass Packaging is a leading supplier of sustainable and infinitely recyclable glass packaging. Ardagh Glass Packaging operates 34 production facilities in North America and Europe, employs approximately 11,600 people and recorded revenues of $3.3 billion in 2020

Ardagh Group, a leading global supplier of infinitely recyclable metal and glass sustainable packaging solutions, has today published its new Sustainability Report 2021, which announces the launch of ambitious new long-term targets for Ardagh Metal Packaging and Ardagh Glass Packaging. These new targets include zero waste to landfill by 2025, a 10% VOC emission intensity reduction, a 20% water use intensity reduction and are aligned with the Science Based Targets Initiative for Greenhouse Gas emissions.

Ardagh’s new sustainability targets include a commitment to achieving 100% renewable electricity to operate its facilities. Ardagh’s Renewable Energy Programme aims to source 100% of its annual electricity demand from renewable sources by 2030. “Through the transition to renewable energy, we aim to reduce our Scope 2 CO2 emissions to zero by 2030,” said John Sadlier, Ardagh Group Chief Sustainability Officer. “We will achieve this with a combination of on-site, near-site and offsite renewable energy projects across our European and Americas facilities footprint.”

In addition to its new sustainability targets, Ardagh will continue to place greater emphasis on social sustainability focusing on our people and our communities. Having previously announced a major multi-year grant to Project Lead The Way to deliver Science, Technology, Engineering and Mathematics (STEM) education to students across the U.S., their latest sustainability report shares an ambition to run similar programmes across Europe and South America.

“As a supplier of infinitely recyclable packaging solutions, Ardagh has a responsibility to improve the emissions, ecology and social pillars of our sustainability strategy,” said Paul Coulson, Ardagh Group Chairman & CEO. “We look forward to further enhancing our products by innovating and collaborating along our supply chain to achieve continued sustainability success with customers and suppliers and a better future for everyone.”

Yesterday, on the occasion of the 26th U.N. Climate Change Conference of the Parties (COP26), Ardagh announced the signatory of a Letter of Intent (LOI) with its partners Diageo, Dassault Systèmes and Exxergy. Under the LOI the partners will collaborate on a new innovative technology to make glass bottles stronger while reducing their weight and therefore carbon footprint.

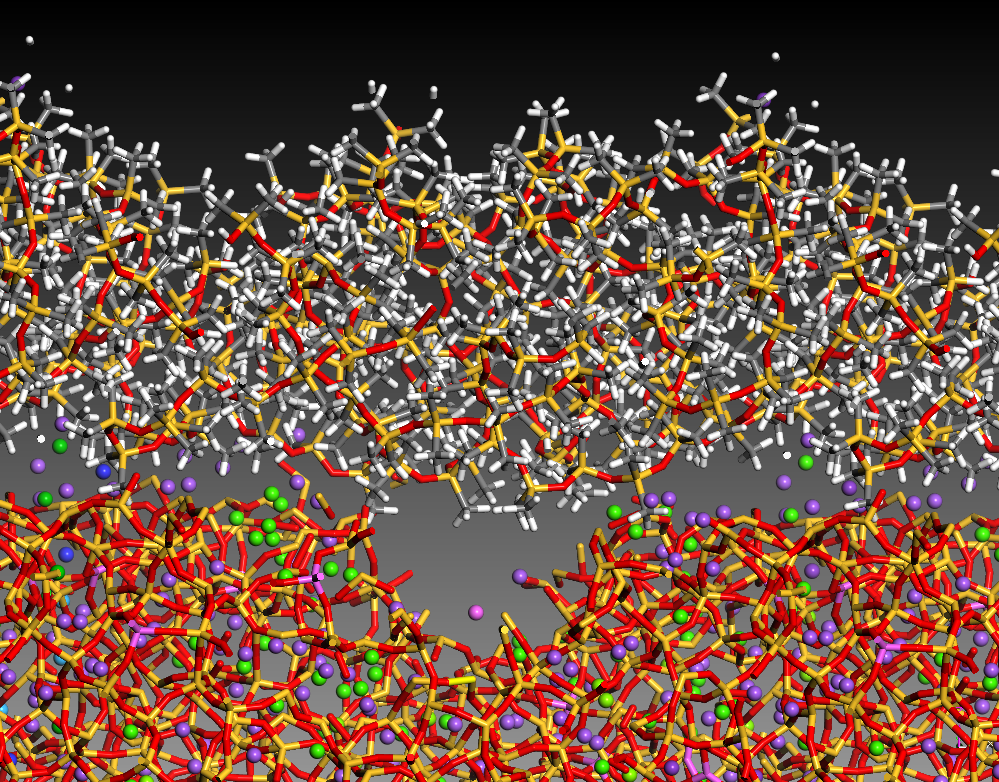

Monahan Road, Cork, Ireland — Nov. 9, 2021 - Three industry leaders in sustainable solutions for the glass industry are coming together to collaborate on innovative technology to increase the strength and thereby significantly reduce the weight of glass bottles. Dassault Systèmes, Ardagh Group and EXXERGY will begin ‘virtual twin’ trials on Diageo’s iconic Johnnie Walker bottle in January 2022 to research and develop a coating that will enable the glass bottle to be lightweighted without compromising its strength and shape – an industry first.

The virtual trial will pioneer science-based sustainable innovations to reduce the time and cost needed to test glass products, while also reducing the raw materials and energy used in the process. A virtual twin is a real-time digital representation of a product or process that is used to model, visualise and predict new innovations before any physical trials take place. The trial will research and develop a new external coating for the glass bottle to reduce the naturally occurring micro-cracks in the glass surface, which will allow the glass to be much lighter while maintaining its strength. The lightweight glass bottle will maintain its 100% recyclability and if successful in the virtual trial, will undergo glass bottle testing from summer 2022.

Ardagh Group, a leading global supplier in sustainable packaging solutions, will work with EXXERGY, an international consulting firm active in the renewable and glass sectors, to research and develop the coatings for global beverage leader Diageo, makers of Johnnie Walker, Smirnoff and Gordon’s gin. Dassault Systèmes will provide contract research services using its BIOVIA applications to create a nanoscale virtual twin of the coatings, simulate their interaction with the surface of the glass, and test their efficacy.

John Sadlier, Chief Sustainability Officer at Ardagh Group, commented on the upcoming product development: “Ardagh Group has pioneered the lightweighting of glass and as a leading global supplier of infinitely recyclable, sustainable metal and glass packaging, we have a responsibility to respond to the sustainability challenges we all face. Together with our customers and supply chain partners, we are eager to explore the potential of digitalisation to drive new and innovative lightweighting solutions.”

Glass lightweighting is one of the solutions for reducing the glass sector’s CO₂ impact and carbon emissions will be reduced in both the manufacturing of the bottle and transportation of the finished goods. Should this collaboration project be successful, it will be a major breakthrough for virtual twin technology in supporting the sustainability ambitions of the glass industry and enabling the decarbonisation of the sector as a whole.

“There is a growing urgency to change our ways of production and consumption. We need to rethink everything, and dare to imagine the boldest sustainability initiatives,” said Florence Verzelen, Executive Vice President, Industry, Marketing & Sustainability, Dassault Systèmes. “Using Dassault Systèmes’ virtual twin technology, companies can design and simulate radically different new sustainable materials, products and processes in record time. They can be right, but also sustainable the first time.”

“At Diageo, sustainability and particularly sustainable packaging is a key priority. We’re excited to be part of this pioneering trial that embraces the principles of our Diageo Sustainable Solutions platform which encourages innovation and collaboration in developing scientific solutions to the impact of climate change. We’ve made a commitment in our Society 2030 strategy to have net zero carbon emissions across all operations by 2050 or earlier, and should this trial be successful, it’s a great step towards us achieving that”, said Lucy Fishwick, Head of Procurement – Grain to Glass Sustainability, Diageo.

About Ardagh Group

Ardagh Group is a global supplier of infinitely recyclable metal and glass packaging for brand owners around the world. Ardagh operates 57 metal and glass production facilities in 12 countries, employing over 16,000 people with sales of approximately $7bn.

About Dassault Systèmes

Dassault Systèmes, the 3DEXPERIENCE Company, is a catalyst for human progress. We provide business and people with collaborative 3D virtual environments to imagine sustainable innovations. By creating virtual twin experiences of the real world with our 3DEXPERIENCE platform and applications, our customers push the boundaries of innovation, learning and production. Dassault Systèmes brings value to more than 290,000 customers of all sizes, in all industries, in more than 140 countries. For more information, visit www.3ds.com

3DEXPERIENCE, the Compass icon, the 3DS logo, CATIA, BIOVIA, GEOVIA, SOLIDWORKS, 3DVIA, ENOVIA, NETVIBES, MEDIDATA, CENTRIC PLM, 3DEXCITE, SIMULIA, DELMIA, and IFWE are commercial trademarks or registered trademarks of Dassault Systèmes, a French “société européenne” (Versailles Commercial Register # B 322 306 440), or its subsidiaries in the United States and/or other countries.

About Diageo

Diageo is a global leader in beverage alcohol with an outstanding collection of brands across spirits and beer categories. These brands include Johnnie Walker, Crown Royal, J&B, Buchanan’s and Windsor whiskies, Smirnoff, Cîroc and Ketel One vodkas, Captain Morgan, Baileys, Don Julio, Tanqueray and Guinness.

Diageo is a global company whose products are sold in more than 180 countries around the world. The company is listed on both the London Stock Exchange (DGE) and the New York Stock Exchange (DEO). For more information about Diageo, our people, our brands, and performance, visit us at www.diageo.com. Visit Diageo’s global responsible drinking resource, www.DRINKiQ.com, for information, initiatives and ways to share best practice.

About EXXERGY

EXXERGY is a German-based network of leading expert consultants specializing in the renewable energy and the glass industries. EXXERGY has experience in technical optimization, business and financial strategy development and implementation, organizational development and change management. Two features of EXXERGY’s work are its innovation capability, for example, the development of a technical rating system for renewable energy assets and development of the glass strengthening technology, and its contribution to the public good, for example leading the development of conformity assessment for renewable energy through IECRE.

EXXERGY has subsidiaries in Switzerland, in the USA, and in China.

The glass packaging supplier wins the coveted award for outstanding quality and service

Ardagh Glass Packaging has been a major supplier of Edrington’s spirit bottles for over 30 years, producing premium bottles for brands such as The Famous Grouse and Brugal rum.

In revealing the spirit producer’s overall choice of Supplier of the Year 2020, Edrington commented that they were impressed with Ardagh’s 100% quality record during the year.

Ardagh Glass Packaging Sales Director UK, Nick Witton, said:

“This is a great result for the business, and I’d like to say a huge thank you to all the teams at Irvine, Barnsley and Knottingley in the UK who have delivered the quality that has made us stand out, particularly during the huge challenges of 2020.”

In addition to the coveted Supplier of the Year award, Edrington also presented Ardagh with a Gold award for their 2020 performance – another outstanding achievement.

Ardagh and Edrington have recently signed a long-term contract for increased volume in the UK and for Brugal rum in the Dominican Republic.

Ardagh Glass Packaging is a leading supplier of sustainable and infinitely recyclable glass packaging. Ardagh Glass Packaging operates 34 production facilities in North America and Europe, employs approximately 11,600 people and recorded revenues of $3.3 billion in 2020

Sidel has successfully installed its first high-speed PET packaging line for water in Baghdad as part of the greenfield project of Iraqi National Company for industrial food (Iraqi National for Food). With a speed of 48,000 bottles per hour (bph), the outstanding line efficiency of 96% corresponds closely with the high sustainability standards and right-weighting expertise in packaging design provided by Sidel. The new Dinar bottle produced for Iraqi National for Food comes in three sizes and is manufactured with the lightest preform on the market, based on Sidel’s StarLite™ design.

Iraqi National for Food belongs to the Iraqi National Group of Companies, which is one of the country’s leading companies in manufacturing, trade and transportation. Founded in 2019, Iraqi National for Food is recognised for its high-quality nutritional products. The company has many self-owned brands – including “Hindrin” carbonated soft drinks, “Dinar” healthy water and “Ra’eege” pasteurised juice.

Iraqi National for Food initiated the new greenfield project to meet a growing demand for bottled water. After witnessing and experiencing first-hand Sidel’s solutions at two customer sites in Turkey, Iraqi National for Food chose Sidel as their partner to install the complete PET water packaging line.

Two firsts in Baghdad: Sidel’s high-speed PET water line and the lightest preform

Following an analysis of the market and the customer’s requirements, Sidel proposed a complete PET packaging line for water featuring a Sidel Combi as a turnkey solution, covering the entire process from packaging design to equipment supply. It thus became Sidel’s first and fastest high-speed line in Baghdad. The 48,000 bph line has a line efficiency of 96%. The complete line solution not only ensures high efficiency and quality, but also high sustainability standards which are of utmost importance to Iraqi National for Food. For example, at the beginning of the line, Sidel’s EvoBLOW blower fitted with the AirEco2 double air-recovery option reduces the required volume of compressed air by 35%. Furthermore, the Sidel Matrix Filler SF100 reduced filler enclosure provides a smaller filling environment with fewer chemicals and less water used during external cleaning. The air filtration system used in the filling process keeps the environment safe while ensuring high product quality.

In terms of packaging design, the bottle is designed and manufactured in three sizes (330 ml, 500 ml, 1500 ml) with one of the lightest preforms on the market (StarLITE base), further enhancing the product’s sustainability.

Close cooperation overcomes lockdown obstacles

To complete the installation on time, Sidel and Iraqi National for Food cooperated closely during this period, overcoming numerous logistic challenges posed by the lockdown further to the COVID-19 pandemic. “The situation made the process of dispatching our installation team as well as arranging spare parts more difficult. Although the line arrived at the site before the lockdown, the project execution was still hindered by the restrictions, especially because no one was allowed to travel to Iraq at the time. By tackling the dilemma together with the customer, Iraqi National for Food managed to arrange an exceptional flight for our team a few months after the lockdown,” explained Vedat Guler, Sales Director – Middle East at Sidel.

The installation and start-up only took six weeks and the first sellable bottle was produced and launched on the market by the middle of June 2020. “We are very happy that we chose Sidel for our complete water line project, in particular during the pandemic. The Sidel team provided great consultancy and conducted efficient execution so that our product could be launched in a short period of time,” said Mohammed Jasim, Executive Manager at Iraqi National for Food.

Sidel is a leading global provider of packaging solutions for beverage, food, home and personal care products in PET, can, glass and other materials.

Based on over 170 years of proven experience, we help shape the factory of tomorrow, through advanced systems and services, line engineering, eco-solutions, and other innovations. With over 40,000 machines installed in more than 190 countries, Sidel has 5,000+ employees worldwide who are passionate about providing equipment and service solutions that fulfil customer needs.

We continuously ensure we understand the evolving business and market challenges our customers face and commit to meeting their unique performance and sustainability goals. As a partner, we apply our solid technical knowledge, packaging expertise and smart data analytics to assure lifetime productivity at its full potential.

Thanks to enhanced performance, Sidel’s Super Combi Compact complete water line opened the door for more business opportunities for Zulal Water Factory, in Sharjah, UAE (Zulal). Running at up to 45,000 bottles per hour (bph), the line not only delivers increased productivity by 280%, but also helps the company save 56% on energy costs, when compared with their existing PET line. In addition, with the new, lighter PET bottle and optimisation of utilities, there has been a considerable reduction in the overall carbon footprint.

Zulal was established by H.H. Sheikh Dr. Sultan Bin Mohammed Al Qasimi, Supreme Court Member, and Ruler of Sharjah, which is part of SEWA (Sharjah Electricity and Water and Gas Authority) in the UAE. The company’s vision is to provide clean, pure drinking water for all people in the region. In 1995, Zulal was the first government organisation to address this requirement. It is the only water enterprise that provides 100% pure groundwater directly from the Hamdah wells in Sharjah. The water is certified by international standards and packed according to the highest international standards for packaging drinking water.

The connection between Zulal and Sidel can be dated back to the late 1990s, when Zulal first installed a Sidel blower. In 2019, the company reached out to Sidel again for a new high-speed line to meet market demand. As a complete line solution provider, Sidel consulted the customer on packaging design and line capacity, as well as line design and layout to enhance the overall performance.

Greater productivity opens the door for more business opportunities

After 18 months of discussion, Sidel provided Zulal the Super Combi Compact water line, running at up to 45,000 bph. The layout was a key element of the line design for this project, because the line had to be installed in the existing location. Sidel experts managed to accommodate the configuration of the Super Combi Compact and conveyors, as well as two packers, into that space, thereby achieving approximately a 25% overall space saving due to the redesigned “Accumulation, Combiner and Labeller”.

The new line provided Zulal with greater line efficiency and productivity enabling further business opportunities. “After installing Sidel’s complete water line, we now have the capacity to supply our products to major airlines, hotels, schools and offices. We are really pleased with the enhanced performance,” said Mr. Ali Ahmed Ali Al Kindi, Manager of Zulal Department at SEWA. As Sidel’s motto goes “Performance through understanding”, continuous communication with clear information played a key role in this cooperation to better understand consumer’s needs and achieve goals.

New bottle design and production line aligning with sustainability goals

In line with SEWA’s sustainability policy, Zulal wanted to optimise its carbon footprint. By redesigning the PET bottles, and reducing the weight, the new bottle for 330ml and 500ml formats now weigh just 9.75g and 12.5g, which saved up to 0.65gm and 1gm respectively per bottle. It also contributes to reducing Zulal’s carbon footprint with considerable PET savings, namely an estimation of saving 215kg for 330ml and 331kg for 500ml per shift production run. Additionaly, thanks to Sidel’s complete line solution, Zulal pays 56% less for energy, while increasing the productivity by 280% compared to their existing lin

Sidel is a leading global provider of packaging solutions for beverage, food, home and personal care products in PET, can, glass and other materials.

Based on over 170 years of proven experience, we help shape the factory of tomorrow, through advanced systems and services, line engineering, eco-solutions, and other innovations. With over 40,000 machines installed in more than 190 countries, Sidel has 5,000+ employees worldwide who are passionate about providing equipment and service solutions that fulfil customer needs.

We continuously ensure we understand the evolving business and market challenges our customers face and commit to meeting their unique performance and sustainability goals. As a partner, we apply our solid technical knowledge, packaging expertise and smart data analytics to assure lifetime productivity at its full potential.

The company's board of directors approved the divestment of the remaining 51 percent shareholding in Max Speciality F

AMP, part of the Ardagh Group, says it will represent an investment of about $200m (£149m).

The one thing that you will find in abundance on the internet is creativity.

Mondi, a leading global packaging and paper company, is investing €20 million to further improve the sustainability of its pulp production at the Frantschach mill in Austria. The mill, which is celebrating its 140th anniversary in 2021, has already been self-sufficient in terms of energy for many years and supplies surrounding communities and industrial companies with surplus heat from the pulp production process.

“Today, the focus on sustainability and circularity puts fibre-based products, and pulp, right into the spotlight. Not only is wood a renewable resource, but we know that paper is the most widely recycled material in the world with, for example 74% of paper and 83% of paper-based packaging in Europe being recycled. Our new plant equipment will make our pulp production even more efficient and sustainable. The modernisation and expansion of the evaporation plant increases the amount of heat extracted and reduces the need for steam. It also reduces the chemical oxygen demand of the biological waste water treatment by 140 tonnes per year”, says Gottfried Joham, Managing Director of Mondi Frantschach.

The decision to invest was driven by the need to make best use of wood as a primary input.

In this specific case, the proportion of tall oil, which can be used in the production of paints, adhesives, or films, will be increased from 18 kg to 35 kg per tonne of pulp.

Construction of the new evaporation plant will start immediately and commissioning will take place in autumn of 2023.

Mondi Frantschach produces kraft papers that are mainly used for food, building materials, and animal feed. Mondi’s sustainability ambitions are demonstrated by its Mondi Action Plan 2030 (MAP2030) framework: by focusing on circular driven solutions, created by empowered people, taking action on climate the Group believes it will have the most impact in achieving positive change and contributing to a circular economy.

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is integrated across the value chain – from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer-centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2020, Mondi had revenues of €6.66 billion and underlying EBITDA of €1.35 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

About Mondi Kraft Paper

Mondi Kraft Paper is part of Mondi’s Business Unit Flexible Packaging and the global leading producer of high-quality bleached and unbleached sack kraft paper and bleached, unbleached and recycled speciality kraft paper grades, as well as bleached and unbleached market pulp with certified wood. Our world-class integrated mills offer paper grades for numerous applications that can be converted into strong yet lightweight industrial paper sacks for cement, building materials, food, agricultural or chemical industries, to shopping bags for retailers, e-commerce packaging, and insulation papers that are sustainable by design. Our R&D Centre in Frantschach, Austria continuously optimises production processes to develop smarter and more sustainable packaging solutions by putting a focus on meeting the highest environmental standards. We have more than 100 years of expertise in papermaking and have four operations in Austria, Bulgaria, the Czech Republic and Sweden.

Berry M&H has responded to growing demand for a larger size Boston Round bottle with the introduction of a one litre version for its popular PET Forest range.

The extended range now comprises sizes from 200ml to one litre, providing a comprehensive choice – including the provision of family ranges – for a wide variety of products including personal care, household and industrial. To help customers meet their sustainability goals, the bottles can also be manufactured incorporating up to 100% post-consumer recycled (PCR) material.

The new one litre size has been designed with both 28/410 and 28/415 neck options, making the bottle suitable for existing filling lines. Berry M&H offers an extensive selection of cap options to provide a complete pack and closure solution.

For many products, the clarity of the PET bottle enhances on-shelf impact and appeal. Importantly, clear, labelled bottles are fully recyclable at their end of life.

For brands requiring additional individualisation, high-quality printing can be utilised throughout the bottle’s large decoration area, and it can also be produced in a variety of colours, although these options will impact on the bottle’s ability to be recycled.

The M&H Boston Round ranges are also available in HDPE, with the choice of materials further widening the types of applications for which the bottles are suitable.

For more information on the Boston Round and Berry M&H’s many other ranges of packaging solutions, visit www.mhplastics.com.

A 32-head multihead weigher from Ishida Europe is providing fast and accurate weighing of mixed bags of quality chocolates for Chocolates Valor, one of Spain’s leading chocolatiers.

The Ishida CCW-RV-232B has the ability to handle two, three or four products simultaneously for discharge into the same bag, giving Chocolates Valor the flexibility to respond to changing customer orders. During the peak four months in the run up to Christmas the machine is operating 24 hours a day, handling 1.6 tons of product every hour.

The weigher is packing a variety of bag sizes - 180g, 250g, 470g and 1kg – for both Chocolates Valor’s own brands and private label. Speeds are restricted by the current manual packing of filled packs into cartons, but the machine is running at up to 80 packs per minute on the 470g pack. Changeovers can be carried out quickly by calling up the stored pre-sets on the intuitive and easy to use touchscreen remote control unit. The ease of use of the machine means that just one operator is now required to manage the entire line.

The 32 heads of the weigher are divided into sections to handle the different products – for a four-mix product, therefore, eight weigh hoppers are dedicated to each sweet variety with a second set of booster hoppers (fitted underneath each weigh hopper) doubling the number of available hoppers to 16 for each mix section . All weigh and booster hoppers utilise the Ishida RV’s unique triple combination calculation software that can calculate three optimal weight combinations, double check them and then select the one nearest to the target weight - all in a single cycle.

Chocolates Valor reports that the Ishida weigher is achieving excellent accuracy to within a few grams of the target weight. This is particularly important for some products where there is a guaranteed number of items in each pack, meaning the weigher is able to deliver this with only minimum giveaway. The company anticipates that payback on the weigher will be within just two years.

This is the second Ishida multihead weigher installed at Chocolates Valor’s factory in Villajoyosa, near Alicante. The company also operates a 14 head weigher for packing mono products into bags, and this made Ishida the natural choice when it needed a mixed weighing solution to meet the requirements of a major customer.

“We know Ishida weighers for their high performance, reliability and ease of operation, and the company offered the best solution on the market for our requirements,” comments Pedro Miguel Marcet Arlandiz, Chocolate Valor’s Engineering Manager. “The 32 head weigher gives us the flexibility to meet a variety of pack sizes and has the capacity and consistency to maintain production targets, particularly during the peak Christmas season.”

The Ishida weigher was supplied to Chocolates Valor by Ishida’s long-standing Spanish distributor CIMA, who also provided the conveyors and multi-product feed system to deliver product to the top of the weigher. In addition, full training on the machine was given to Chocolates Valor’s operators during installation.

Established in 1881 and now run by the fifth generation of the López family, Chocolates Valor produces a range of exquisite chocolates and chocolate bars, along with a range of desserts and chocolate drinks. During the 1960s, the company adopted its quality strategy and launched Pure Chocolate, a product that has become an emblem of the brand. Vegetable fats are not used as a substitute for cocoa butter in the manufacture of the product. Today Chocolates Valor continues to source the finest cocoa beans from different parts of the world in its exclusive recipes which are the result of over 130 years of experience and best practice.

Berry Global is introducing its next generation of innovation with a range of packaging and product solutions, the Berry Global B Circular Range, that leverages the company’s engineering expertise and proprietary processes in the design for circularity to reduce products’ impact on the environment, focused on helping brand owners meet and exceed their sustainability goals.

Recognising the growing importance of action to support brand sustainability objectives, Berry Global has decided to take on even the toughest personal care customer packaging challenges utilising its global scale to access circular resins, worldwide capabilities and growing investments in infrastructure such as the recently announced Berry Leamington Spa recycling facility. The Berry Global B Circular Range programme will see the ongoing introduction of a range of standard products for the beauty, personal care, pharmaceutical, food, beverage, home care and industrial sectors, all of which feature important sustainability enhancements.

The first collection of the Berry Global B Circular Range of products for personal care applications, which is now being launched, is designed in line with two key rules of the Circular Economy: design out waste and pollution and keep product and material in use. This process includes the incorporation of recycled content; the development of reusable and refillable packs; and the development of mono-material solutions to improved recyclability.

Highlights from the first suite include Boston Round bottles and Flip Top and Tube closures incorporating up to 100% post-consumer recycled (PCR) plastic; refillable jars with up to 100% PCR content; a lighter weight mono-material lip care stick and refillable roll-on stick; as well as airless dispensers with lighter weight and mono-material construction, recycled content and refillable capabilities.

Equally important, all sustainability benefits are being introduced while ensuring that each product remains fit for purpose, with the required levels of protection, preservation and convenience for the end-consumer.

In conjunction with the new standard collection, Berry has a long history of working in close partnership with its customers in the development of more sustainable solutions tailored to their precise requirements, utilising its in-depth knowledge and experience, and keeping customers up to date with the latest advances in resin material science, manufacturing, and design for circularity.

“We recognise the importance that companies across all markets attach to sustainability. As an industry leader in helping brand owners, large or small, achieve their sustainability commitments, we are excited to launch the Berry Global B Circular Range to help bring solutions toward a circular economy to market faster,” commented Thierry Bernet, Circular Economy Director, Berry CPI. “Whether seeking a special product solution or establishing a corporate-wide initiative, we will partner with customers to help them towards meeting both short- and long-term sustainability goals.”

Mondi, global leader in packaging and paper, commissioned a life cycle assessment (LCA) comparing its new ground-breaking paper pallet wrapping innovation, Advantage StretchWrap, with conventional plastic stretch film wrapping. The full study was conducted by an external consultancy, is ISO-compliant and includes an external critical review. Based on the assumption that both materials are recycled at the end-of-life, the findings showed that the paper-based pallet wrapping by Mondi has a lower climate impact as one of the LCA indicators.

The basis of comparison is the potential environmental impacts arising from wrapping one pallet. The LCA examined 16 indicators to understand potential trade-offs between the two materials. It covers all relevant life cycle stages, from raw material extraction, production, up to the application on a pallet at the customer. In addition, the impact of the end-of-life stage is assessed.

The LCA found that Advantage StretchWrap has 62% lower greenhouse gas (GHG) emissions when compared to virgin plastic stretch film, and 49% lower GHG emissions when compared to plastic stretch film made with 50% recycled content. Advantage StretchWrap has a lower environmental impact than plastic in a number of categories including climate change and fossil resource use. The plastic stretch film did perform better in some indicators, such as land use and freshwater eutrophication.

Karoline Angerer, Product Sustainability Manager Kraft Paper & Paper Bags, Mondi, says: “Given the complexities of material choice, we see independent critical reviews as essential to ensuring LCAs that deliver objective and reliable results focusing on the environmental benefits of each material. At Mondi, we use these results as part of our decision-making process in line with our MAP2030 sustainability commitments. Our customers value our attention to detail and how we partner using our EcoSolutions approach to develop solutions that are sustainable by design.

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is integrated across the value chain – from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer-centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2020, Mondi had revenues of €6.66 billion and underlying EBITDA of €1.35 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

About Mondi Kraft Paper

Mondi Kraft Paper is part of Mondi’s Business Unit Flexible Packaging and the global leading producer of high-quality bleached and unbleached sack kraft paper and bleached, unbleached and recycled speciality kraft paper grades, as well as bleached and unbleached market pulp with certified wood. Our world-class integrated mills offer paper grades for numerous applications that can be converted into strong yet lightweight industrial paper sacks for cement, building materials, food, agricultural or chemical industries, to shopping bags for retailers, e-commerce packaging, and insulation papers that are sustainable by design. Our R&D Centre in Frantschach, Austria continuously optimises production processes to develop smarter and more sustainable packaging solutions by putting a focus on meeting the highest environmental standards. We have more than 100 years of expertise in papermaking and have four operations in Austria, Bulgaria, the Czech Republic and Sweden.

• Event on November 9-11 offers chance for industry stakeholders to view Airnov’s range of sustainable healthcare packaging solutions.

• Airnov awarded EcoVadis certification after making series of sustainable operational and product improvements.

• Certification underlines Airnov’s commitment to make life better for healthcare patients while minimizing its impact on the environment.

– Airnov, a global leader in innovating packaging solutions for the healthcare market, will be showcasing its range of solutions at the CPhI Worldwide expo in Milan.

Held on November 9-11, the event is one of the leading expos bringing together suppliers and buyers across the entire pharma value chain.

Visitors will be able to explore a variety of Airnov products at the event, including DRICARD™, lasermarked canisters, laser-marked stoppers, light desiccant stoppers, and more, all of which are evidence of the company’s commitment to produce sustainable solutions for the healthcare packaging sector.

Indeed, Airnov will be demonstrating its sustainability credentials at CPhI. For example, the company was recently accredited with EcoVadis certification as it continues to incorporate sustainable innovation into its products and operations.

Airnov France has enrolled onto EcoVadis program, which helps organizations to enhance their sustainable credentials by identifying areas for improvement through a comprehensive ratings process.

This year, Airnov’s French plant has been granted certification for continuous improvement across a range of processes, including waste management, energy consumption and use of raw materials.

“We are pleased to announce our new partnership with EcoVadis in 2021 to evaluate and recognize the engagements and improvements of Airnov France across key areas such as the environment, sustainable procurement, labor and human rights, and ethics,” said Stephane Rault, Global Product Manager.

“These are continuous actions we will push for over the comings years across all of the regions we operate in.”

In France, these actions have included enhancements based on customer feedback to Airnov’s core packaging solutions used in the pharmaceutics, nutraceutics, diagnostic and probiotics markets – many of which will be on display at CPhI Worldwide.

Specifically, plastic weight has been reduced across several product lines, including Airnov’s light desiccant stopper and new DRICARD™, which has doubled performance with a 50% reduction of raw materials (plastic and ink) used.

The company has also adopted laser marking techniques to reduce the need for labels, inks and adhesives.

Meanwhile, a greater use of secondary bulk packaging (large bags instead of carton) is helping to make the transport of products around the world more environmentally friendly. Airnov is also working to optimize the transportation process through a commitment to fill containers, thereby reducing the amount of wasted container space.

Mélissa Plantier, Product Manager at Airnov, added: “Airnov is concerned about the protection of the environment and strives to minimize its global impact by improving its production and operational processes, as well as product design. “Raw material optimization and reduced energy consumption reduction are just the first of many steps that Airnov has committed to along its path for a more sustainable impact.”Airnov invites visitors to CPhI Worldwide to visit its booth (2B60C) during CPhI Worldwide, which runs from November 9-11 at Fiera Milano.

In fact, the Wales-based company uses AMP’s sophisticated matte finish for every can across its entire product line,