Today, edible oil is a very competitive market category, essentially driven by product and brand differentiation as well as competitiveness through packaging cost savings, production efficiency and permanent asset optimisation. Sidel, as a leading solution provider, have a strong heritage in edible oil, acting as a one-stop shop partner in proposing complete and integrated PET lines. The company’s strength is also based on their comprehensive portfolio of equipment capable of answering any request in terms of PET bottles, labels, caps, secondary packaging, footprint and line speeds along with ensuring an overall technical coherence, an adapted level of investment and an optimized return on investment (ROI).

Currently, a number of trends are strongly shaping the production environment of edible oil producers: product diversification and tough competition, asking for cost savings, are driving the industry. “Product diversification is bringing more product shapes, sizes and SKUs to handle for the producers, therefore, the need for more flexible lines and equipment is rising,” says Francesca Bellucci, Marketing Director for the Food, Home & Personal care market categories at Sidel, “regardless, whether we are talking about capital expenditures (CAPEX), operating expenses (OPEX) or total cost of ownership (TCO), all that nowadays matters to edible oil producers.”

Sidel’s 40-year heritage in PET packaging, coupled with the company’s cutting-edge equipment, prove to be instrumental in helping producers active in this market segment to step up quickly. Sidel are able to provide edible oil producers with assistance very early in the value chain with engineering services for the line design and packaging design capabilities.

“Built into our very roots, our holistic approach to the edible oil industry contributes to delivering the right level of performance our customers need. At Sidel, we genuinely believe that achieving optimum quality and safety levels while lowering costs and optimising assets along the line lifecycle is most easily achieved with a one-stop shop partner,” explains Francesca Bellucci.

Secured performance and TCO with coherent complete line solutions

Being a global solution provider for complete and integrated lines, Sidel are capable of adapting each and every component of the line to perfectly fulfil edible oil producers’ expectations or specific needs.

Industrial turnkey line solutions with in-line PET bottle blowing are a promising approach to boost edible oil producers’ productivity from the beginning to the end of the line due to a coherent process and flow management. A great example is Sidel’s partnership with B.L. Agro Industries Ltd., an Indian-based manufacturer of edible oils, for which Sidel have successfully provided over the past five years, three different lines with different approaches, challenges and objectives to bottle sizes, shapes, secondary packaging and line speed. “Sidel greatly supported us along the whole journey,” says Ashish Khandelwal, Executive Director at B.L. Agro. “Relying on a single supplier who takes the full line responsibility including packaging, was a great help, especially because whatever we produce must adhere to the highest quality standards,” he adds.

For Sidel as well as for B.L. Agro, line control and automation are at the heart of the system, ensuring the continuous running and the overall performance of the line. “In terms of efficiency, we are now reaching 98.5% on our first line, running at 24,000 bottles per hour (bph) with our small format bottles and 97.6% on our second one at 6,000 bph for the big containers. Our third line is currently being ramped up, but we fully trust to achieve efficiency up to 90% in two or three weeks’ time,” explains Ashish Khandelwal.

Single supplier with large portfolio adapted for every need

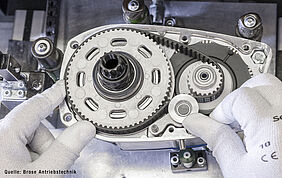

Sidel have a deep knowledge at each step of the line with leading-edge equipment and state of the art technology.

On the wet part of the line, capabilities in blowing, filling, capping and labelling have to be available for every need or speed to address the various market demands. This has also been the case for B.L. Agro over the past years: From stand-alone blowers being able to manage small bottles at high speed or large bottles with the creation of notches for the insertion of a handle, up to Combi blowing, filling and capping solutions to reduce space and minimize the risk of cross-contamination, Sidel have really expressed the breadth of their blowing capability at B.L. Agro packaging facility.

Sidel’s portfolio also guarantees various options for labellers, supporting wrap around or pressure sensitive labels as well as bottle/pack/pallet conveyors and accumulation tables.

End-of-Line solutions: Flexibility at all levels

The End-of-Line solutions, i.e. the packing, shrink-wrapping and palletising solutions, are also a critical part of the complete line, especially when it comes to SKU multiplication and the flexibility required to pack them.

“For our 200 ml, 500 ml, and 1 L bottles, we use American boxes (RSC), while for our 2 L and 5 L bottles, we use Wrap-Around blanks,” explains Ashish Khandelwal. Sidel have been able to install a case erector, a vertical robotic packer and a case gluer, answering the need of RSC, while for the two other lines with two drastically different levels of speed, B.L. Agro chose Cermex WB46 intermittent case packer for the low speed line and VersaWrap® continuous packer for the most recent high speed line.

Equally significant next to answering the operational needs with the right level of technology, Sidel have been able to adapt and support B.L. Agro with the expected level of investment or CAPEX.

“We are happy to have found a complete line solution under one roof. Our production costs have been drastically reduced. Perhaps we are one of the most efficient in the industry in terms of hygiene as well as operational efficiency,” concludes Ashish Khandelwal.

Further details on Sidel’s complete line solutions for edible oil are available at

https://www.sidel.com/en/home-personal-care-pharma-ca-7.

Editors Note: The images within this document are for illustrative purposes only and should not be used for reproduction. If high resolution copies are not attached with the document, please contact Nikolaus Schreck at F&H Porter Novelli for copies – see contact details below.

-----------------------------------

For editorial, advertising and sponsorship enquiries, please contact:

F&H Porter Novelli

Nikolaus Schreck, Senior Consultant

Tel: +49 (0) 89 12175-123

Email:

sidel@fundh.de