Covid vaccine packaging group doubles wa...

West specialises in packaging for injectible drugs.

West specialises in packaging for injectible drugs.

Shareholder advocacy firm As You Sow submitted a proposal requesting shareholders vote to have Amazon issue a report

Endeavour Group’s wine bottling and packaging arm Vinpac Internationa

BiofuelCurrently, German biogas specialist WELTEC BIOPOWER is building a biomethane plant for the Spanish dairy cattle farm Torre Santamaría. Since the first 250-kW biogas plant went live back in 2011, the Catalan family business has been able to cover its entire energy demand from its own residues. The farm in Vallfogona de Balaguer was the first milk producer in Spain to use any residual materials for the production of energy.

The investment in the new RNG/ biomethane plant amounts to more than €4 million, a quarter of this sum will be spent on modernising the existing infrastructure and biogas plant. One of the reasons why Catalonia‘s second-largest dairy producer is able to allocate a budget of this magnitude is that the biomethane sales had already been contractually secured at an early stage. The green gas is to be marketed as climate-friendly fuel via an energy service provider. „We view this AD plant as an environmental investment, as it allows us to cut our own greenhouse emissions almost to zero and generate additional income from biomethane“, explains Juan Bautista Pons Torrades, Managing Director and owner of Torre Santamaría.

Besides its pioneer spirit in environmental topics, the cattle farm in the province of Lleida is also a trailblazer in other areas. For example, Torre Santamaría was one of the first to introduce the well digestible A2 milk. Moreover, in 2019, the business was the first dairy cattle farm to be certified by the Lactalis Group in recognition of its animal welfare efforts. The dairy group Lactalis purchases some 22 million liters of milk a year from Torre Santamaría and sells it under various brands.

„To produce this amount of milk, we keep 2,300 dairy cows and 2,100 calves on an operating area of 14.2 hectares“, says Juan Bautista Pons Torrades. Every year, some 60,000 t of input substances accumulate for use in the biogas production. Cattle manure accounts for about 90 percent of the substrates. Bedding consisting of ground straw as well as silage leftovers are also fed into the digester. Currently, WELTEC is setting up two additional stainless-steel digesters for the digestion of all residues on the farm. Each of the digesters has a height of 6.30 m, a diameter of 26.87 m and a capacity of 3,573 m³. „After processing the biogas generated in the digesters, Torre Santamaría feeds 300 standard m³/h of biomethane into the natural gas grid“, reports Mark Kornweibel, the Spanish sales partner of WELTEC BIOPOWER.

According to Kornweibel, the existing 250-kW cogeneration power plant will continue to be operated despite the transition to RNG production. The farm is thus able to cover its own demand for power, heat and hot water. After the new plant is finished in summer 2021, Torre Santamaría will continue to satisfy its demand for energy from its own raw material. Moreover, the plant operation enables the Catalans to shoulder their corporate social responsibility and maintain a healthy balance between environment, social concerns, economic factors as well as security of food and energy supply.

The transportation & storage of BioHazardous Materials such as medical specimens, medical waste and virulent, inf

Travagliato, Italy – Antares Vision, a leading global provider of intelligent track & trace, inspection and smart data management solutions for the life science, food & beverage, nutraceuticals and cosmetics sectors, has introduced a dedicated high-resolution vision system providing comprehensive inline layout inspection for webs and labels. Easily integrated into new or existing labeling, printing or packaging machines, the new AV Print Inspector offers 100% inspection for the increasingly sophisticated, often print-on-demand applications common in modern product marking operations.

AV Print Inspector offers whole-label inspection at speeds up to 80 meters/minute. The technology supports all major vision system tools for seamless quality control across a wide array of layout features, including 1D/2D barcodes; optical character recognition (OCR) and verification (OCV); pattern matching; color check; and pattern matching.

Robust and efficient, AV Print Inspector can define as many as 40 unique regions of interest, each with independent parameters and reportable defect statistics. The result is 100% inspection of all common defects, including dots, smudges, marks, missing or discolored lines, and missing or incorrect barcodes or human-readable data.

The system is as flexible as it is exacting: AV Print Inspector can either conduct quality control by referring to an imported image, such as a PDF, or via an algorithm that automatically calculates the inspection parameters, discriminating between fixed and variable data. Inspection formats can be created directly by operators using an intutive graphic user interface (GUI) that does not require significant coding or vision systems experience. AV Print Inspector’s recipe management module has virtually unlimited storage capacity, and the 21CFR/11 compliant system can automatically generate batch and audit trail reports.

AV Print Inspector’s standard head size handles labels and web applications up to 4 inches wide, with 6” and 12” options also available.

"With brand owners in various markets increasingly demanding completely defect-free labeling and print-on-demand operations, solutions like the AV Print Inspector that replace manual sampling with automatic, 100% quality control will become the new norm," said Chris Collins, North American Sales Manager for Antares Vision. "Not only does the AV Print Inspector guarantee a virtually defect-free print application, its in-line inspection dramatically reduces materials waste for a lower-cost, more eco-friendly process."

# # #

About Antares Vision

Listed since April 2019 on the Italian Stock Exchange in the AIM Market, the Antares Vision Group guarantees protection of products, people and brands through inspection systems for quality control, track & trace solutions for anti-counterfeiting and supply chain transparency, smart data management tools for maximized efficiency and digitalization of the supply chain, from raw materials to final consumers. The Antares Vision Group is active in the pharmaceutical market and in Life Science in general (biomedical devices and hospitals), as well as in beverage, food, cosmetics and consumer-packaged goods.

The Group reaches over 60 countries with complete and flexible solutions, hardware and software, with related services and a worldwide network of more than 40 partners. Thanks to its two founding partners’ 20 years of vision technologies experience, the Antares Vision Group is the supplier of 10 out of 20 leading pharmaceutical companies in the world, with more than 25.000 inspection systems that ensure everyday product safety and quality, 6.500 quality controls and over 3.500 serialization modules installed worldwide.

In 2019, founding partners Emidio Zorzella and Massimo Bonardi were recognized with the Ernst & Young “Entrepreneur of the Year” award for innovation. For more info: www.antaresvision.com.

Auburn, AL, April 28, 2021 – Aptar CSP Technologies, a leader in material science and active packaging solutions (part of AptarGroup, Inc.), announced its Activ-Film™ technology protects two new at-home COVID-19 tests that recently received Emergency Use Authorization (EUA) from the U.S. Food and Drug Administration (FDA).

The tests were developed by a leading manufacturer of diagnostic healthcare solutions and offer prescription and OTC (Over the Counter) COVID-19 at-home testing options without the need to visit a doctor’s office

Aptar CSP’s Activ-Film™ technology is integrated into the dipstick of the diagnostic kits to protect against moisture and other environmental conditions that could otherwise impact test accuracy. Activ-Film™ leverages Aptar’s proprietary 3-Phase Activ-Polymer™ platform technology, which provides a broad spectrum of customized and highly-engineered solutions in a variety of configurations, such as Activ-Vial™ for housing diagnostics strips and dipsticks, and Activ-Tab™, which is integrated within diagnostic cassettes. This material science-based active packaging technology currently protects a range of lateral flow, molecular, and electrochemical diagnostic test kits on the market today, including Quidel® Corporation’s QuickVue® Influenza and COVID-19 tests.

“As we continue to navigate through the COVID-19 crisis, this game-changing solution will help meet the urgent demand for COVID-19 testing in communities around the world,” said Badre Hammond, Vice President Commercial Operations, Aptar CSP Technologies. “We are committed to leveraging our material science expertise to enable our partners to meet the ongoing need for innovative healthcare solutions that help improve and save lives. This is another example of the value we bring to the market when sensitive diagnostic elements need protection.”

More information about the new at-home COVID-19 tests is available on the FDA website.

##

About Aptar CSP Technologies

Aptar CSP Technologies is part of AptarGroup, Inc., a global leader in the design and manufacturing of a broad range of drug delivery, consumer product dispensing and material science solutions. Aptar’s innovative solutions and services serve a variety of end markets including pharmaceutical, beauty, personal care, home, food and beverage. Using insights, proprietary design, engineering and science to create dispensing, dosing and protective packaging technologies for many of the world’s leading brands, Aptar in turn makes a meaningful difference in the lives, looks, health and homes of millions of patients and consumers around the world. Aptar is headquartered in Crystal Lake, Illinois and has 13,000 dedicated employees in 20 countries. For more information, visit www.aptar.com.

Aptar CSP Technologies is global material science company providing innovative, highly-engineered active packaging solutions to protect sensitive products. CSP is a responsive, flexible partner committed to offering customers a single, reliable source for custom product design, development, and manufacturing. CSP has a proven track record of pioneering technological solutions that ensure product protection and enhance its customers’ brand equity. For more information, visit www.csptechnologies.com.

In the wake of acute shortage of tinplate/ tin-free steel material which is largely used to manufacture cans and cont

Early this month, the ALDI supermarkets in Australia joined other international arms of the Germany-based supermarket

This new feature is now available on our multi-award-winning labelling app LabelLogic Live: quick and simple-to-use s

OSHKOSH, Wis. – AmPrima™ forming film from Amcor – the leading global developer and producer of responsible packaging – has received prequalification to carry the store drop-off label from the How2Recycle® program. The innovative technology paves the way for a true recycle ready forming/non-forming flexible solution for consumer packaging applications.

AmPrima forming film is fully compatible with the Amcor portfolio of AmPrima PE Plus recycle ready non-forming materials, which can be paired with EZ Peel® technology for effortless opening convenience. The advance offers brand packagers a more sustainable, high-performance alternative to one of today’s most popular packaging formats.

“AmPrima forming film is an exciting option for companies seeking a future ready solution that provides quantified environmental improvements. Switching to AmPrima forming film can reduce carbon footprint up to 69% compared to the incumbent nylon forming films. AmPrima forming technology is an important milestone in our commitment to make all of our packaging recyclable or reusable by 2025,” said Amcor Flexibles North America Sustainability Director Fabio Peyer.

The clear, high-barrier material delivers a true “drop-in” alternative to today’s traditional non-recyclable nylon forming films. “AmPrima forming film drives our circular economy forward, providing a more sustainable choice without compromising performance, barrier properties or consumer appeal,” Peyer said. “Our film runs on existing HFFS or thermoforming production lines and will not impact line speed, seal integrity or yield.”

Because the How2Recycle program has prequalified AmPrima forming film for the store drop-off label, the process of packaging development and label application is significantly simplified. “With the AmPrima portfolio, customers can take a concept straight from package development to requesting usage of the How2Recycle store drop-off label,” Peyer said.

Without prequalification status, brand owners must engage independent labs to verify that prospective packaging structures satisfy the requirements of the How2Recycle program for standardized labelling.

Beyond assessing scientific test data and regulatory trade claims, the approval process assures material recyclability in accordance with the Association of Plastic Recyclers, evaluating collection (access to recycling), material sortation, reprocessing and end market use.

Final approval for carrying How2Recycle’s store drop-off label is subject to conditions like product application and final package design. Approved for clean and dry content, AmPrima forming film positions brand owners of popular applications such as hot dogs, string cheese or lunchmeat to be recycle ready when curbside recycling infrastructures become more commonly available.

Currently available in a broad range of formats, Amcor’s AmPrima recycle ready solutions provide customers with a more sustainable flexible packaging choice to meet growing consumer and retail demand for recyclable packaging.

Media Contact Information

Mary Johnson, Marketing Communications Director

Amcor Flexibles North America

920-527-5134 | mary.johnson@amcor.com

About Amcor

Amcor is a global leader in developing and producing responsible packaging for food, beverage, pharmaceutical, medical, home- and personal-care, and other products. Amcor works with leading companies around the world to protect their products and the people who rely on them, differentiate brands, and improve supply chains through a range of flexible and rigid packaging, specialty cartons, closures, and services. The company is focused on making packaging that is increasingly light-weighted, recyclable and reusable, and made using an increasing amount of recycled content. Around 47,000 Amcor people generate US$12.5 billion in sales from operations that span about 230 locations in 40-plus countries. NYSE: AMCR; ASX: AMC

About How2Recycle

The How2Recycle® label is a U.S. and Canada-based standardized labeling system that clearly communicates recycling instructions to the public. Over 275 brand owners and retailers are members of How2Recycle, and tens of thousands of products carry the How2Recycle label in the marketplace. How2Recycle is a project of the Sustainable Packaging Coalition®, a membership-based group that brings together business, educational institutions, and government agencies to collectively broaden the understanding of packaging sustainability and develop meaningful improvements for packaging solutions. How2Recycle and Sustainable Packaging Coalition are a part of GreenBlue, a 501(c)(3) nonprofit based in Charlottesville, Virginia, United States. For more information, follow us on Twitter @How2Recycle or go to our website at www.How2Recycle.info. Companies interested in joining How2Recycle can visit http://how2recycle.info/join for more information or contact how2recycle@greenblue.org.

Mondi, a global leader in packaging and paper, is supplying customers with its innovative and sustainable containerboard grade made in Slovakia from renewable materials. Kraft Top White combines the strength, printability and appearance benefits of a white fresh fibre top layer with the advantages of a recycled fibre bottom layer.

State-of-the-art paper technology increases strength while reducing weight, making Kraft Top White a compelling solution for the growing European white top liner market for use in shelf-ready packaging, point-of-sale displays, trays, e-commerce packaging, consumer durables and other customised packaging applications. The Ružomberok mill enjoys a central location in the growing European containerboard market and can therefore offer reduced delivery lead times to customers across Europe for these new paper solutions.

Mondi’s annual 300,000 tonnes Kraft Top White capacity is unmatched in Europe. Production of the two Kraft Top White grades – ProVantage Smartwhite and ProVantage Topwhite – has been ramping up since PM19 started-up in January. At full capacity, the machine will use more than 200,000 tonnes of paper for recycling per year (mainly from Slovakia), opening new processing capacities and supporting the circular economy by keeping materials in circulation and preventing waste.

Mondi’s purpose is to contribute to a better world by making innovative, sustainable packaging and paper solutions. Our new paper machine in Slovakia enables us to offer customers a high-quality new containerboard solution, while further improving the environmental footprint of our Ružomberok mill. Despite the challenges of operating during the pandemic, the local team executed this complex project safely and efficiently, and we are proud of the positive impact that 125 new permanent jobs will have on the local community.

Markus Gärtner, CEO Corrugated Packaging at Mondi

The new paper machine is part of Mondi’s extensive €370m modernisation programme at the Ružomberok mill over the past two years. The fully integrated pulp and paper mill has undergone major upgrades including an automatic warehouse storage area for end products, a recycled paper line, a recycled storage area. Work was also undertaken to improve the wastewater treatment plant. It now produces biogas as a by-product which is used at the plant's boilers, consequently reducing the mill's use of fossil fuels. Avoiding waste, keeping materials in circulation and reducing its own greenhouse gas emissions in line with science-based targets are a key focus of MAP2030, Mondi’s 10 year Action Plan on sustainability.

Technical details

For further information on Mondi’s sustainability ambitions and 10 year Action Plan, MAP2030, click here.

Contact

Iris Perz, External Communication Manager

Tel: +43 1 79013 4610

Email: Iris.Perz@mondigroup.com

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is integrated across the value chain – from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer-centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2020, Mondi had revenues of €6.66 billion and underlying EBITDA of €1.35 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

From March 22 onwards, all Damm’s cans, which are supplied by Ball Corporation, are certified according to ASI’s Stan

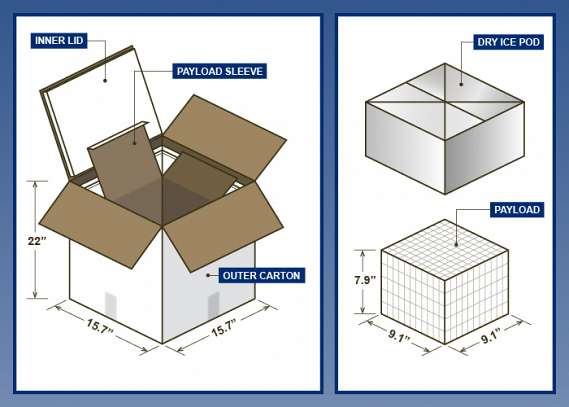

While many of us have been surprised at the speed with which the COVID-19 vaccine has been developed, we may not consider the additional complexity associated with safely transporting it. In the case of one of the available vaccines, Packaging Corporation of America collaborated with several companies to create the best possible solution.

“None of us really knew too much about the vaccine when we started the process back in June 2020,” said Steve Collins, the PCA Sales Representative involved in the project. “You’re making it up as you go, and it’s kind of fun. I know so much now, and it’s very rewarding to me that it’s been an overwhelming success.”

PCA’s expertise in packaging design, coupled with one of our partners’ expertise in cold chain packaging, enabled us to build the right solution. The project presented several challenges, including keeping the box between negative 80 and negative 70 degrees Fahrenheit for 48 hours and being able to insert monitors and dry ice to ensure that the vials stayed in that temperature range.

“We went through 20 to 30 different designs to arrive at the end product,” Collins said. “We needed several different pieces of corrugated to keep the vials suspended and prevent them from touching the dry ice. Our Mooresville, North Carolina, design team did an outstanding job meeting all of these needs.”

Production of the vaccine boxes began in August 2020. Collins highlights the teamwork needed to create a solution that is helping to save lives. “The expectation is high, and our people are committed to doing anything needed to get the job done. I wouldn’t have been able to harness that kind of support from any other company.”

Because of its importance in history, the first shipment — including PCA’s box and all of its interior packaging — recently became part of the Smithsonian National Museum of American History’s exhibit on the global pandemic.

As a result of the pandemic, consumers now place significantly more value on food safety and hygiene and see sustaina

PFE tested a bag made with two layers of film and a polyethylene closure.

People with disabilities are the largest minority group in the world.

06 May 2021 --- Instead of decrying plastic packaging as the root of environmental degradation, Philipp Pap, director

Environmental sustainability is becoming a new standard for pet food packaging. Following the European Strategy for Plastics, by 2030 all plastic packaging in European Union must be recyclable or reusable. However, many businesses are already striving towards achieving this goal by 2025. Recently Coveris, a leading European manufacturer of flexible packaging solutions, supported its key customer in Spain, C&D Foods, in a smooth transition to sustainable mono-material bags. Jérôme Detais, Commercial Manager from Coveris, and Mario de la Fuente, Key Account Manager from C&D Foods explain the key challenges and benefits of their sustainable packaging evolution.

According to latest research, despite the economic crisis due to COVID-19 pandemic, the global pet food production volume exceeded 29,3 million metric tons in 2020, driven mostly by Europe . However, it’s not the market demand that is keeping the pet food brands awake at night, but the rigorous legislation regarding its packaging. “Our number one concern at the moment is to effectively switch our production in next the 5 years to sustainable packaging that is fully recyclable or reusable”, commented Mario de la Fuente from C&D Foods, a key pet food manufacturer in Western Europe. “With the help of Coveris we managed to achieve this for our key private pet food brand without major design changes or production downtime”.

Natural feels better

One of C&D’s top-selling brands is a private dry pet food label sold in Aldi stores across Spain and Portugal under “Natura” brand name. Once the new packaging legislation came into life it was agreed that “Natura” will be the pilot packaging project. After several months of product development, the final bag is based on a flexible mono-material solution called MonoFlexE which Coveris launched at FachPack trade show back in 2019. Designed using only polyethylene, it maintains the best features of standard Coveris films, including enhanced convenience for opening and reclosing, as well as an attractive, premium look at point-of-sale. But most importantly – it offers fully recyclability thanks to its mono-material base. “Redesiging from PET makes separation during recycling process a lot easier and more effective. However, the material change wasn’t the only challenge we had to overcome”, explains Jérôme Detais.

Despite having a fully recyclable bag, C&D Foods also requested a more natural “look & feel”. “Normally we would use a special varnish or an external OPP/PET layer to achieve this effect, but this would make recycling difficult. Therefore, we created the matt-finish effect directly on the outer PE layer, without affecting recycling”, commented Jérôme Detais. Another challenge was the manufacturing process, because PE shrinks at 100-120 degrees Celsius, while PET has a stronger heat resistance of up to 200-250 degrees Celsius. “This was a particularly difficult step because it influenced the overall quality of the bags and speed of their production which the customer wanted to maintain at the same level. Eventually we managed to meet this criteria by perfectly measuring the material’s heat and avoiding shrinkage both on top and side seals”, added Jérôme Detais.

Packaging of the future

“The final result exceeded our expectations”, summarised Mario de la Fuente from C&D Foods, “The new four corner block bottom bag stands out on the shelf with its natural, matt finish and improved graphics which instantly catch the customer’s eye”. Additionally, the resealable zipper prolongs the product's shelf-life and freshness, while the equivalent machinability as standard PET/PE makes introducing MonoFlexE to existing production lines a straightforward procedure. “Combined with full recyclability thanks to its mono-material base, the new bag meets all our needs for user-friendly, sustainable packaging for pet food both today and tomorrow”, added Mario de la Fuente.

“From a Coveris standpoint it’s most important that the mono-material solution for C&D delivers the same protective, functional and shelf life benefits as existing solutions, without compromising on recycling. Keeping in mind the growing need for more recyclable packaging by 2030, it is a significant step forward in supporting the packaging market in reducing environmental footprint”, commented Jérôme Detais.

Nicolas Plantec

Pet Food and HPC Segment Leader

E: Nicolas.Plantec@coveris.com

M: +33 (0)6 09 64 22 72

The company has committed to ambitious actions to meet the scientifically established threshold necessary to keep glo