Labrenta joins forces with guala closure...

The acquisition of the Vicenza-based company specialised in high-end closures has a strategic relevance for Guala Closures. For the Group, the deal represents an important step towards becoming a world leader also in the luxury segment

Milan, July 8, 2022 - Guala Closures – a global leading producer of closures for spirits, wines, beverages and oil bottles – announces that it has reached an agreement to acquire Labrenta. The acquisition will strengthen Guala Closure’s presence in the luxury segment.

Labrenta's current shareholders (Gianni and Amerigo Tagliapietra – CEO and VP Business Development, respectively) will reinvest in Guala Closures and will take on important managerial roles with regards to the group’s luxury closures segment.

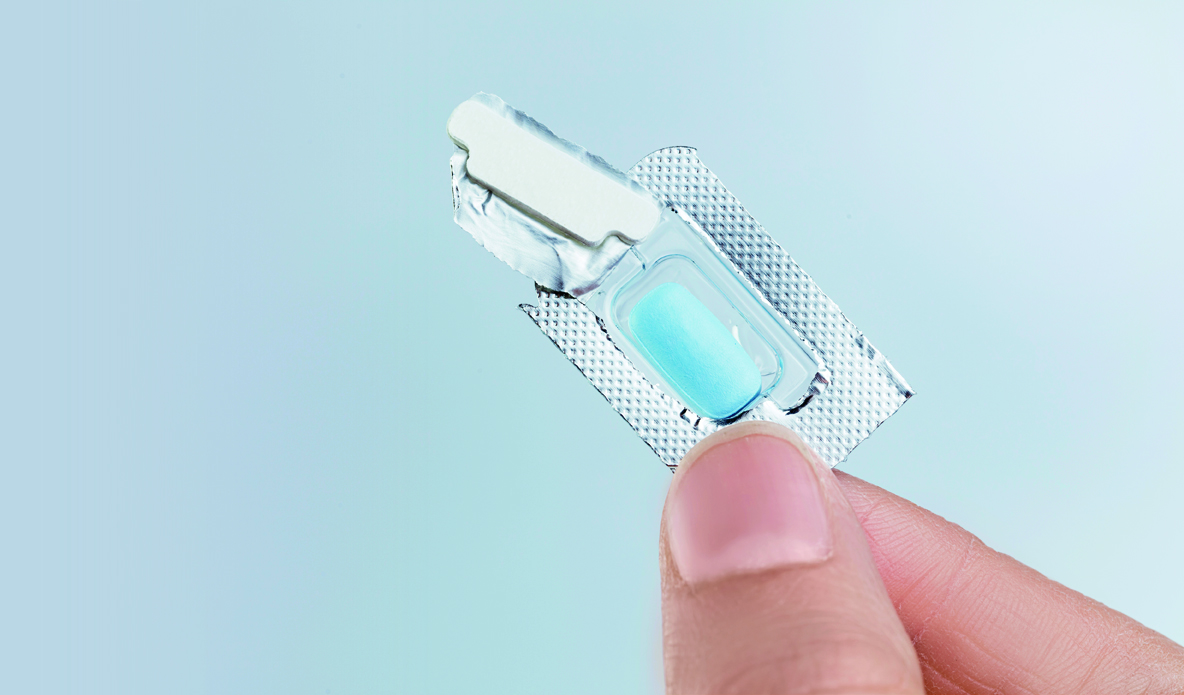

Founded in 1971 by Enzo Tagliapietra in Breganze, Vicenza (Italy), Labrenta is a well-established manufacturer of high-end tailor-made closures for spirits, wine, oil, vinegar and beer. The company, initially founded as a producer of natural cork for the Italian wine market, has grown over the years under the direction of Gianni and Amerigo to establish itself as an international highly innovative firm and obtaining 30 patents. In 2022 Labrenta is expected to achieve more than €30 million in revenues across its 800 customers in 70 countries and has plants in Italy, Brazil and Mexico as well as a commercial branch in the United States. In 2022, the company acquired Anacorks, a Portuguese firm specialised in the production of luxury cork closures. Thanks to its focus on R&D activities, as well as to its attention to sustainability, Labrenta has launched product lines composed of natural and synthetic materials blends, therefore creating innovative and beautifully designed closures.

Innovation and growing attention to sustainability are also among the pillars of Guala Closures' business. The Group currently employs more than 4,850 people, operates in five continents through 30 production facilities with approximately €710 million LTM sales as of 31st of March, 2022.

The acquisition of Labrenta is expected to generate important synergies both at the industrial and commercial level, by offering a full range of products for the fast-growing luxury sector.

Gabriele Del Torchio, President and CEO of Guala Closures, commented: "Labrenta is an excellent and innovative company, with a strong local presence, an important know-how, a well-organised team and a management with a long-term strategic vision. The acquisition of Labrenta represents an important opportunity for our Group. The deal will contribute to the achievement of the goals set in our strategic plan as well as to further strengthen our already significant presence in the luxury segment. The entrepreneurial experiences of Gianni and Amerigo Tagliapietra will be crucial to support us throughout this new development path. The plant in Breganze will become an important centre for research, development and production of luxury closures."

Gianni Tagliapietra, CEO of Labrenta, stated: “Amerigo and I consider Labrenta and its team like a big family, which has grown with us year after year amid challenges and achievements. We wish that it will continue growing strong and succeed in achieving all its goals. Passion for design and technology, production quality, sustainability and a strong team are among Labrenta's core values. In the past years, we have realised how important is for entrepreneurs to be able to respond promptly and effectively to a fast-changing environment. We have found in Guala Closures a group of like-minded people that share our same values, as well as a global leader in the sector that will allow Labrenta to keep pursuing high growth in a well-structured manner."

About Guala Closures Group

Guala Closures Group offers premium and innovative closure solutions that provide protection and convenience to consumers while enhancing customers' brands. A world leader in the production of closures for spirits, wines, beverages, oil and condiments, Guala Closures meets the needs of its customers and their consumers in the global marketplace with innovative and environmentally responsible products. Guala Closures now has more than 4,850 employees, 30 plants on five continents, and products marketed in more than 100 countries. More information is available at: www.gualaclosures.com

About Labrenta

For more than 50 years, Labrenta has been tailoring closures for the beverage and food industries. We proudly design and manufacture our closures in Italy. Love for design and innovation, made in Italy production, sustainability and team are the core values of our reality. We are structured to work with every part of the world, thanks to our subsidiaries in North and South America and partnerships with our distributors and agents. More information is available at: www.labrenta.com.